Stiebel Eltron SHU 5 SLi comfort SMALL WATER

HEATER User Manual

GUARANTEE

ENVIRONMENT AND RECYCLING

INSTALLATION TEMPLATE SHU 5 SLI | SHU 5 SL GB (INSIDE THESE INSTRUCTIONS)

SPECIAL INFORMATION

– The appliance may be used by children aged 8 and older and persons with reduced physical, sensory or mental capabilities or a lack of experience and know-how, provided that they are supervised or they have been instructed on how to use the appliance safely and have understood the resulting risks. Children must never play with the appliance. Children must never clean the appliance or perform user maintenance unless they are supervised.

– In the case of permanent connection to the power supply via a junction box, ensure that the appliance can be isolated from the mains by an isolator that disconnects all poles with at least 3 mm contact separation.

– The power cable may only be replaced (for example if damaged) by a qualified contractor authorised by the manufacturer, using an original spare part.

– Secure the appliance as described in chapter “Installation / Installation”.

– Observe the maximum permissible pressure (see chapter “Installation / Specification / Data table”).

– The appliance is pressurised. During the heat-up process, expansion water will drip from the safety valve.

– Regularly activate the safety valve to prevent it from becoming blocked, e.g. by limescale deposits.

– Drain the appliance as described in chapter “Installation / Maintenance / Draining the appliance”.

– Size the drain pipe so that water can drain off unimpeded when the safety valve is fully opened.

– Fit the drain pipe of the safety valve with a constant downward slope and in a room free from the risk of frost.

– The safety valve drain must remain open to the atmosphere.

1. General information

The chapters “Special Information” and “Operation” are intended for users and qualified contractors. The chapter “Installation” is intended for qualified contractors.

ℹ Note Read these instructions carefully before using the appliance and retain them for future reference. Pass on the instructions to a new user if required.

1.1 Safety instructions

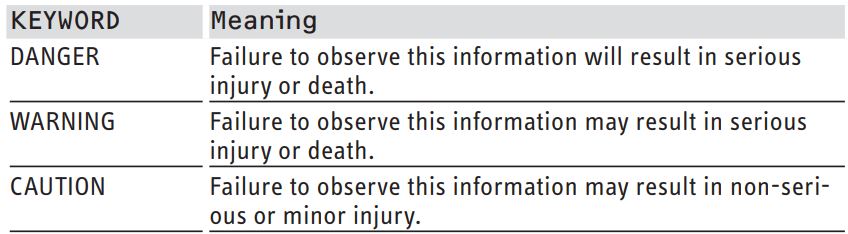

1.1.1 Structure of safety instructions

⚠ KEYWORD Type of risk

Here, possible consequences are listed that may result

from failure to observe the safety instructions.

▶ Steps to prevent the risk are listed.

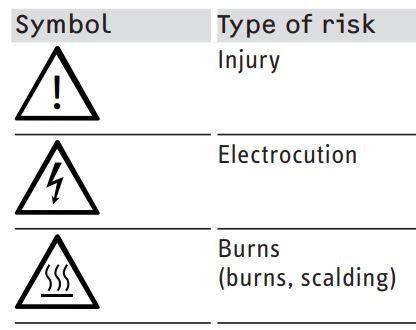

1.1.2 Symbols, type of risk

1.1.3 Keywords

1.2 Other symbols in this documentation

▶ This symbol indicates that you have to do something. The action you need to take is described step by step.

1.3 Units of measurement

ℹ Note

All measurements are given in mm unless stated otherwise.

2. Safety

2.1 Intended use

This sealed unvented (pressurised) appliance is intended for heating domestic hot water. You can use the appliance to supply one or several draw-off points. This appliance is intended for domestic use. It can be used safely by untrained persons.

The appliance can also be used in a non-domestic environment, e.g. in a small business, as long as it is used in the same way.

Any other use beyond that described shall be deemed inappropriate. Observation of these instructions and of instructions for any accessories used is also part of the correct use of this appliance.

2.2 Safety instructions

Where children or persons with limited physical, sensory or mental abilities are allowed to use this appliance, we recommend a permanent temperature limit. A qualified contractor can set this limit.

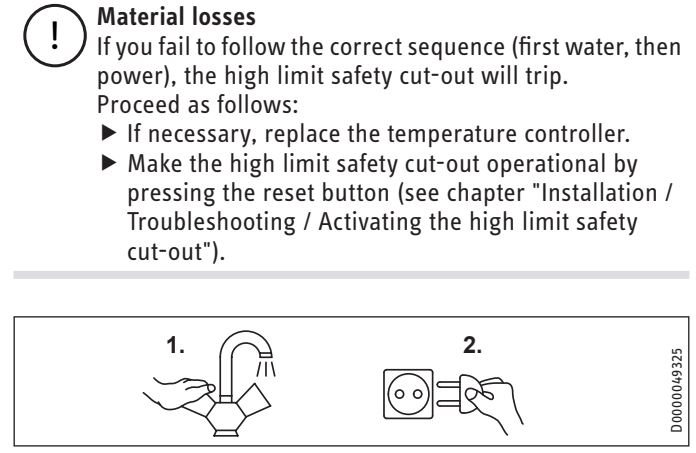

Material losses

If the drain pipe of the safety valve is sealed, the expansion water may cause water damage.

▶ Never close the drain pipe.

Material losses

The user should protect the appliance and its tap against frost.

2.3 Test symbols

See type plate on the appliance.

3. Appliance description

The sealed unvented (pressurised) appliance constantly maintains the water content at the pre-selected temperature. The appliance switches on automatically as soon as its temperature falls below the set value. Subject to season, varying cold water temperatures can result in different maximum mixed water and outlet volumes.

ℹ Note

A qualified contractor can set a temperature limit on the appliance (see “Installation / Settings / Setting the temperature limit”).

ℹ Note

The appliance is under mains water pressure. The water volume increases as the cylinder is being heated up. During this process, expansion water drips out through the safety valve. This is a necessary and normal process.

3.1 Operation

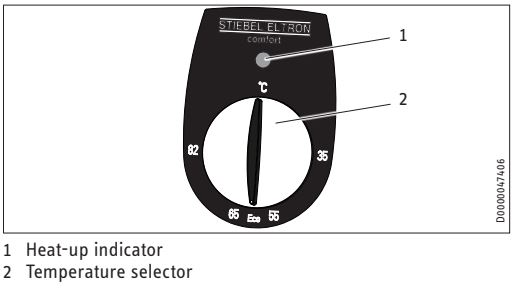

You can set any required DHW outlet temperature at the temperature selector. The heat-up indicator illuminates during the heat-up process.

Depending on the system, the actual temperatures may vary from the set value.

°C = Cold. On this setting, the appliance is protected from frost. The tap and the water line are not protected.

Eco = Recommended energy saving setting (approx. 60 °C), minor scaling

82 = Highest selectable temperature

4. Cleaning, care and maintenance

▶ Never use abrasive or corrosive cleaning agents. A damp cloth is sufficient for cleaning the appliance.

▶ Check the taps regularly. Limescale deposits at the tap outlets can be removed using commercially available descaling agents.

▶ Have the function of the safety assembly checked regularly by a qualified contractor.

Almost every type of water will deposit limescale at high temperatures. This settles inside the appliance and affects both the performance and service life. The heating elements should therefore be descaled if necessary. A qualified contractor who is aware of the local water quality will tell you when the next descaling is due.

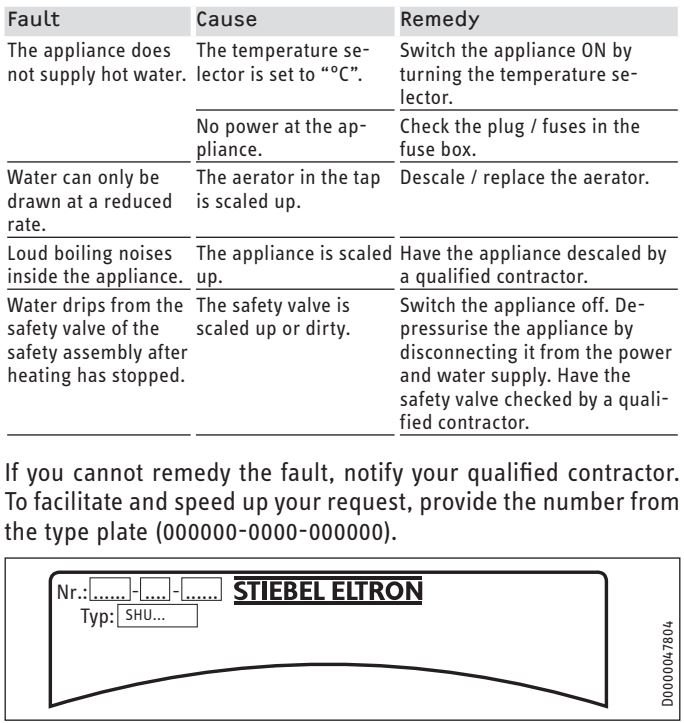

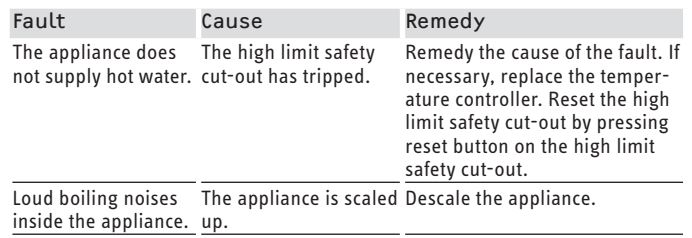

5. Troubleshooting

6. Safety

Only a qualified contractor should carry out installation, commissioning, maintenance and repair of the appliance.

6.1 General safety instructions

We guarantee trouble-free function and operational reliability only if original accessories and spare parts intended for the appliance are used.

6.2 Instructions, standards and regulations

ℹ Note

Observe all applicable national and regional regulations and instructions.

6.3 Information on the safety assembly

If using a plastic stench trap (e.g. DN 40 for the sink), there is no need for the SVMT immersion pipe. Connect the overflow funnel, e.g. using the washing machine connection.

7. Appliance description

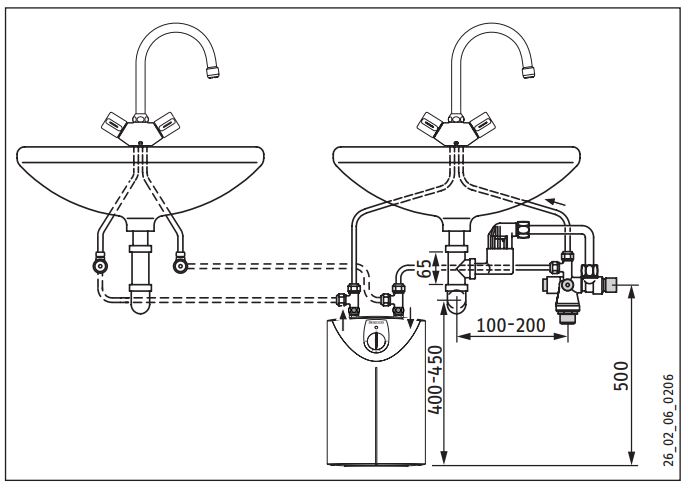

The sealed unvented (pressurised) appliance is only suitable for undersink installation. The appliance is intended for heating cold water and for supplying one or several draw-off points. The appliance may only be installed with pressure taps in conjunction with the SVMT safety assembly (see chapter “Installation / Appliance description / Required accessories”).

7.1 Standard delivery

Delivered with the appliance are the following:

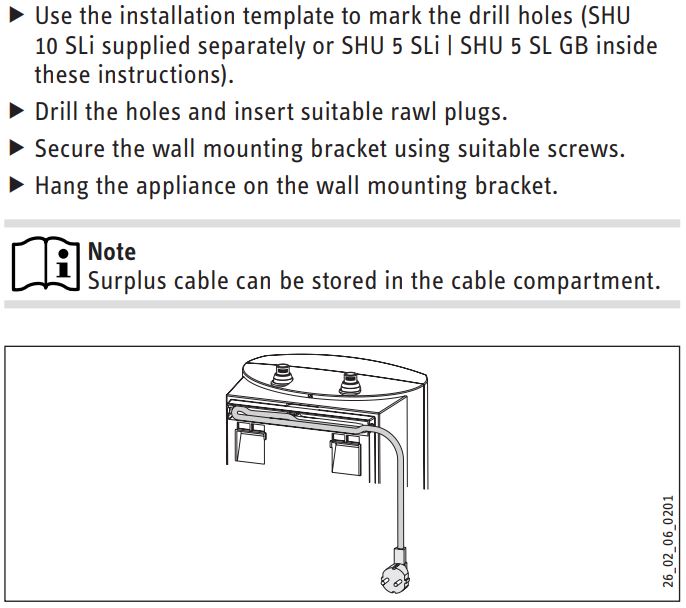

– Wall mounting bracket

SHU 10 SLi

– Installation template

7.2 Required accessories

The following accessories are available for sealed unvented operation:

– SVMT safety assembly for undersink installation

– Water distribution tees

8. Preparation

Water installation

A safety assembly is required.

Taps/valves

Only install pressure taps in conjunction with the SVMT safety assembly.

8.1 Installation site

Always install the appliance vertically and near the draw-off point.

9. Installation

Material losses

When using plastic pipework, observe the extreme operating and fault conditions that can occur on the appliance (see chapter “Installation / Specification / Extreme operating and fault conditions”).

▶ To provide a supply to two washbasins, use the “water distribution tees” (see chapter “Installation / Appliance description / Required accessories”).

▶ Run the connections to the second tap on site, e.g. in 10 mm copper pipe.

9.1 Installing the safety assembly

▶ Fit the safety assembly in the cold water supply line of the appliance.

▶ Observe the information on the safety assembly (see chapter “Installation / Safety / Information on the safety assembly”).

▶ Observe the information in the safety assembly installation instructions.

9.2 Appliance installation

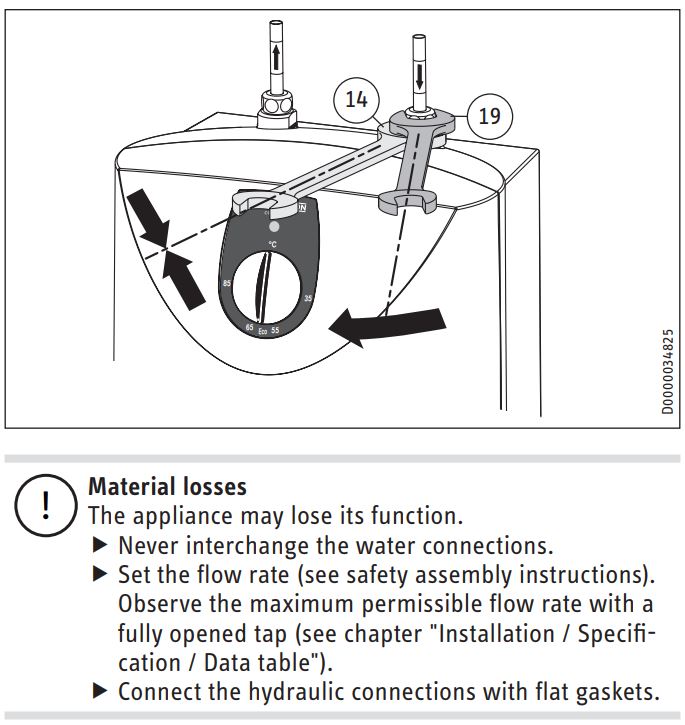

9.3 Water connection

Match up the colour coding on the water connections of the tap and the appliance: – R.h. side blue = “Cold water inlet” – L.h. side red = “DHW outlet”

▶ Secure the tap connections to the appliance.

ℹ Note

Ensure that the water connections are not kinked during installation. Prevent any tensioning during installation.

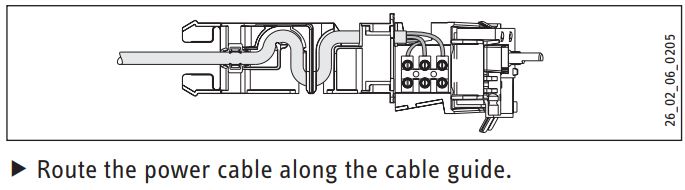

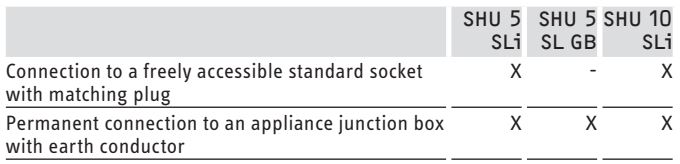

9.4 Power supply

The following electrical connections are permissible:

10. Commissioning

WARNING ELECTROCUTION Commissioning may only be carried out by a qualified contractor in accordance with safety regulations.

10.1 Initial start-up

▶ Either open the DHW valve of the tap or set the mono lever mixer tap to “hot” until the water that flows out is free of air bubbles.

▶ Check the safety assembly. When purging, ensure that a full jet of water flows out.

▶ Insert the plug into the standard socket or set the fuse/MCB in the fuse box.

▶ Select a temperature.

▶ Check the entire hydraulic installation for tightness.

10.1.1 Appliance handover

▶ Explain the functions of the appliance to the user. Show the

user how to operate the appliance.

▶ Make the user aware of potential dangers, especially the risk

of scalding.

▶ Hand over these instructions and, if applicable, the instructions for any accessories.

10.2 Recommissioning

See chapter “Installation / Commissioning / Initial start-up”.

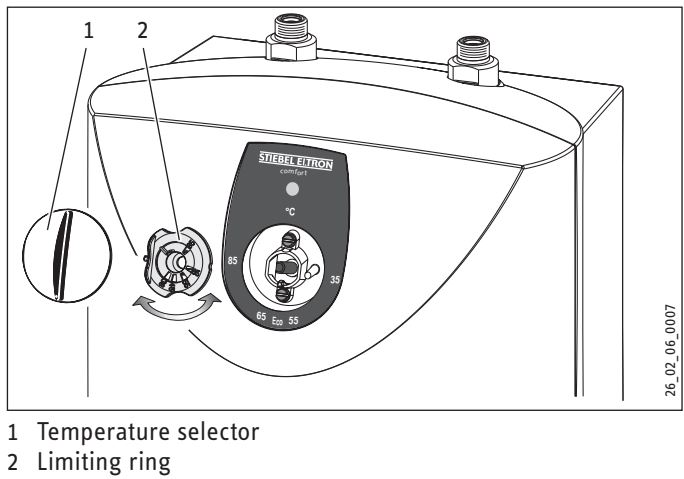

11. Settings

11.1 Setting the temperature limit

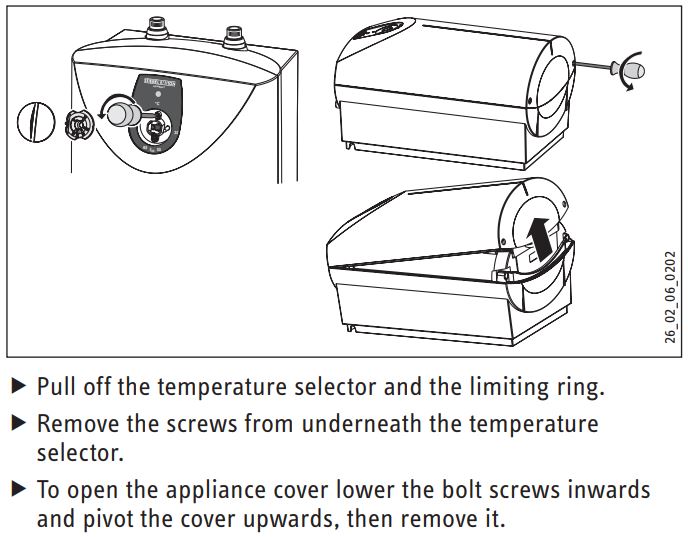

Placing the limiting ring behind the temperature selector allows you to limit the setting range of the temperature selector to a specific maximum temperature.

▶ Turn the temperature selector to zero (fully anti-clockwise to “°C”).

▶ Pull off the temperature selector and the limiting ring.

▶ Push the limiting ring with the required maximum setting onto the controller shaft.

▶ Mount the temperature selector set to zero (°C).

12. Shutdown

▶ Isolate the appliance from the power supply by removing the plug or by tripping the MCB in the fuse box.

▶ Drain the appliance (see chapter “Installation / Maintenance / Draining the appliance”).

13. Troubleshooting

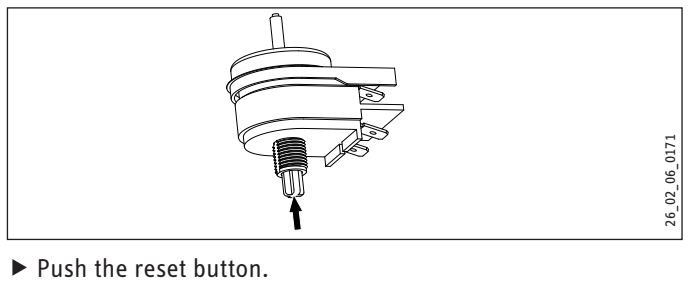

13.1 Activating the high limit safety cut-out

14. Maintenance

WARNING Electrocution Before any work on the appliance, disconnect all poles of the appliance from the power supply.

▶Dismantle the appliance for maintenance work.

14.1 Draining the appliance

WARNING Burns Hot water may escape during draining.

▶ Drain the appliance via its connectors.

14.2 Opening the appliance

14.3 Descaling the appliance

▶ Remove the flanged immersion heater.

▶ Carefully tap the heating element to remove coarse limescale

deposits.

▶ Immerse the heating element up to the flange plate in descaling agent.

14.4 Checking the earth conductor

▶ Check the earth conductor (in Germany DGUV3 for example) across a water connector and the earth conductor contact of the power cable.

14.5 Replacing the power cable

The power cable must only be replaced by a qualified contractor with an original spare part. Alternatively, the H05VV-F3x1.0 cable may be used.

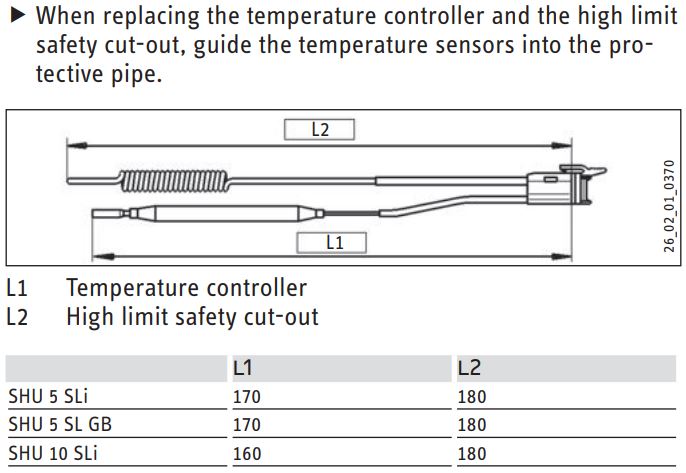

14.6 Positioning the temperature sensor in its protective pipe

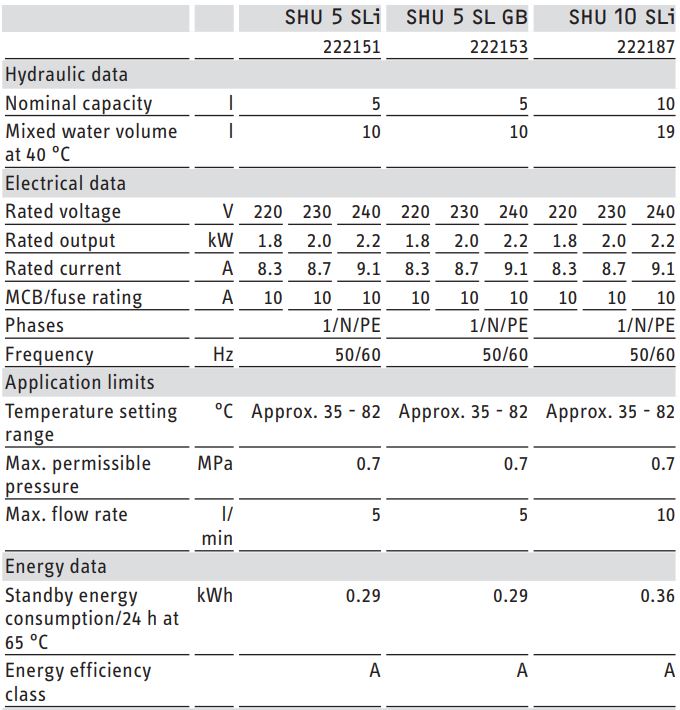

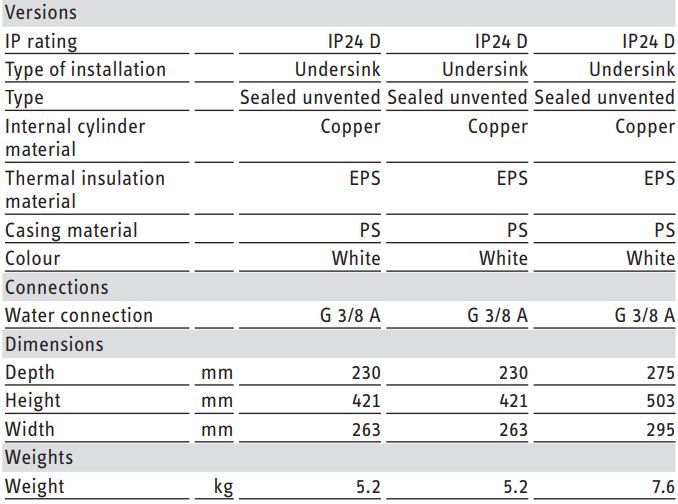

15. Specification

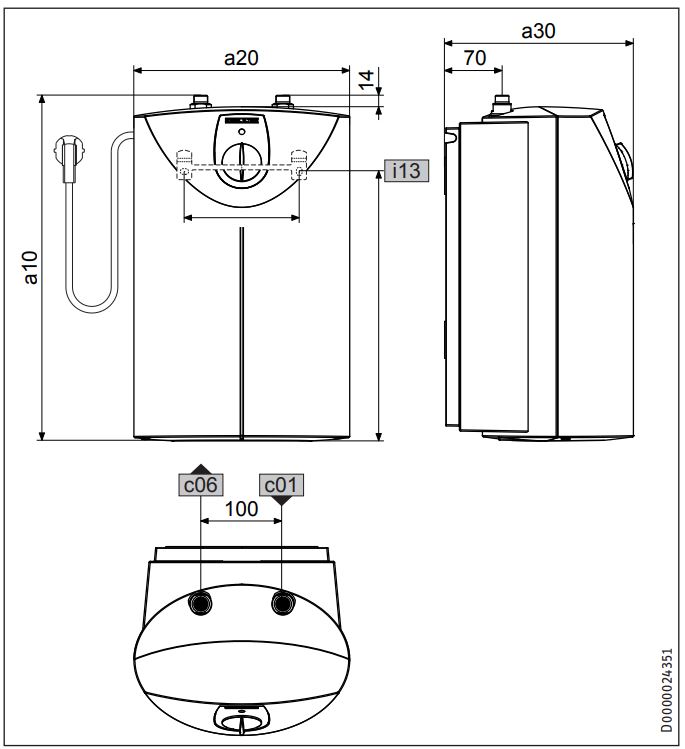

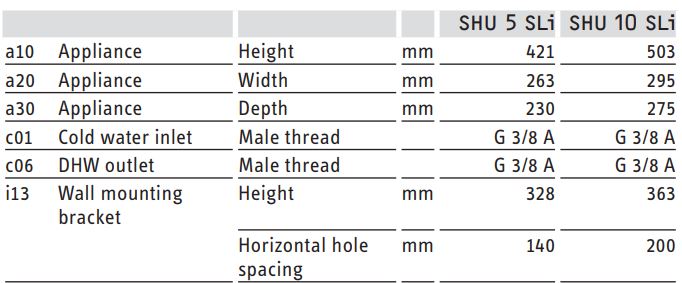

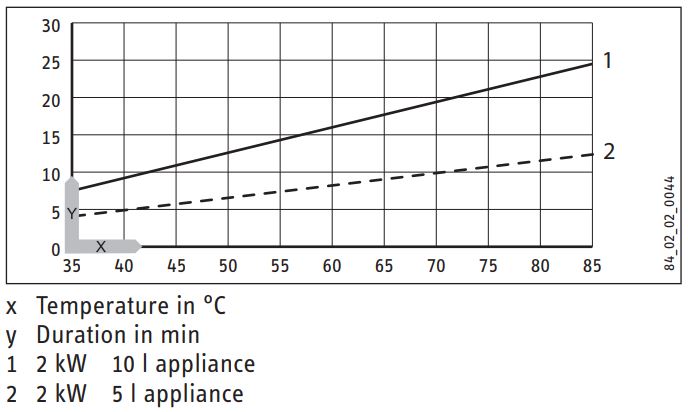

15.1 Dimensions and connections

SHU 5 SLi | SHU 10 SLi

SHU 5 SL GB

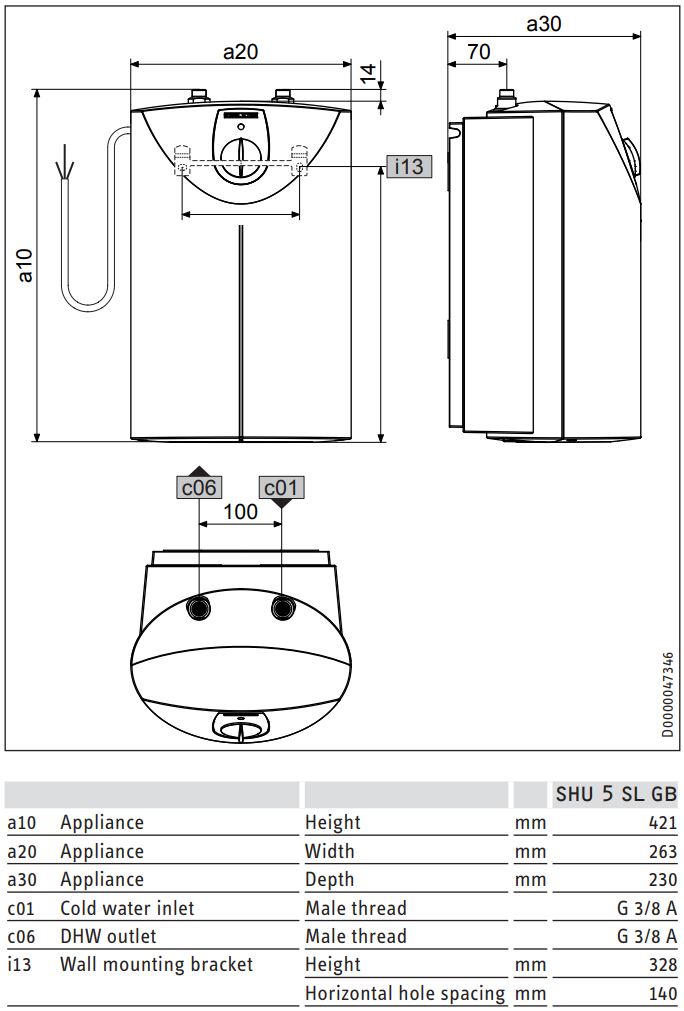

15.2 Wiring diagram

1/N/PE ~ 220 – 240 V

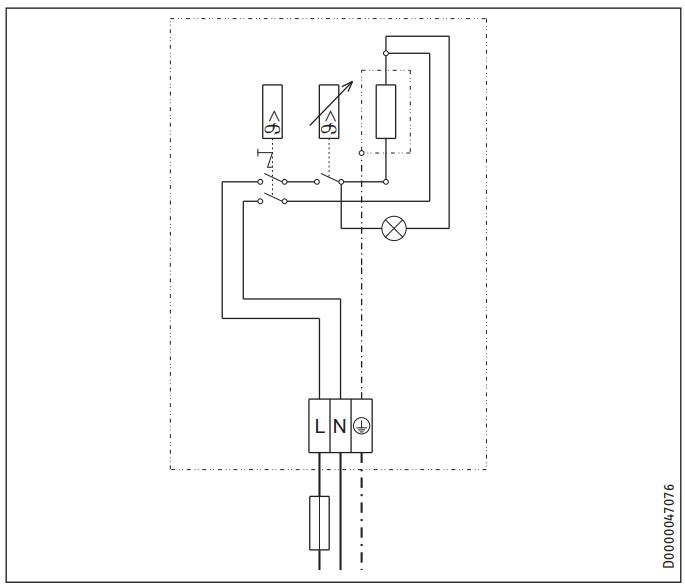

15.3 Heat-up diagram

The heat-up period depends on the degree of scaling and residual heat. For the heat-up time for a cold water supply at 10 °C and a maximum temperature setting, see the diagram.

15.4 Country-specific approvals and certifications

The test symbols can be seen on the type plate.

15.5 Extreme operating and fault conditions

In the case of faults, a peak temperature of up to 105 °C may briefly occur in the system.

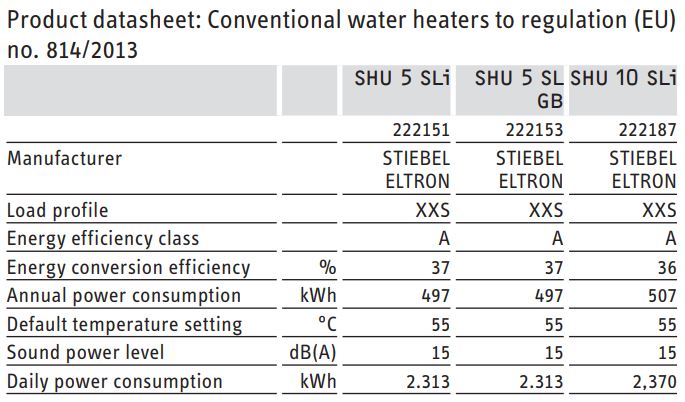

15.6 Details on energy consumption

15.7 Data table

Guarantee

The guarantee conditions of our German companies do not apply to appliances acquired outside of Germany. In countries where our subsidiaries sell our products a guarantee can only be issued by those subsidiaries. Such guarantee is only granted if the subsidiary has issued its own terms of guarantee. No other guarantee will be granted.

We shall not provide any guarantee for appliances acquired in countries where we have no subsidiary to sell our products. This will not affect warranties issued by any importers.

Environment and recycling

We would ask you to help protect the environment. After use, dispose of the various materials in accordance with national regulations.

Deutschland

STIEBEL ELTRON GmbH & Co. KG

Dr.-Stiebel-Straße 33 | 37603 Holzminden

Tel. 05531 702-0 | Fax 05531 702-480

[email protected]

www.stiebel-eltron.de

Verkauf Tel. 05531 702-110 | Fax 05531 702-95108 | info-[email protected]

Kundendienst Tel. 05531 702-111 | Fax 05531 702-95890 | [email protected]

Ersatzteilverkauf Tel. 05531 702-120 | Fax 05531 702-95335 | [email protected]

Australia

STIEBEL ELTRON Australia Pty. Ltd.

6 Prohasky Street | Port Melbourne VIC 3207

Tel. 03 9645-1833 | Fax 03 9645-4366

[email protected]

www.stiebel.com.au

Austria

STIEBEL ELTRON Ges.m.b.H.

Gewerbegebiet Neubau-Nord

Margaritenstraße 4 A | 4063 Hörsching

Tel. 07221 74600-0 | Fax 07221 74600-42

[email protected]

www.stiebel-eltron.at

Belgium

STIEBEL ELTRON bvba/sprl

‘t Hofveld 6 – D1 | 1702 Groot-Bijgaarden

Tel. 02 42322-22 | Fax 02 42322-12

[email protected]

www.stiebel-eltron.be

China

STIEBEL ELTRON (Tianjin) Electric Appliance

Co., Ltd.

Plant C3, XEDA International Industry City

Xiqing Economic Development Area

300085 Tianjin

Tel. 022 8396 2077 | Fax 022 8396 2075

[email protected]

www.stiebeleltron.cn

Czech Republic

STIEBEL ELTRON spol. s r.o.

K Hájům 946 | 155 00 Praha 5 – Stodůlky

Tel. 251116-111 | Fax 235512-122

[email protected]

www.stiebel-eltron.cz

Finland

STIEBEL ELTRON OY

Kapinakuja 1 | 04600 Mäntsälä

Tel. 020 720-9988

[email protected]

www.stiebel-eltron.fi

France

STIEBEL ELTRON SAS

7-9, rue des Selliers

B.P 85107 | 57073 Metz-Cédex 3

Tel. 0387 7438-88 | Fax 0387 7468-26

[email protected]

www.stiebel-eltron.fr

Hungary

STIEBEL ELTRON Kft.

Gyár u. 2 | 2040 Budaörs

Tel. 01 250-6055 | Fax 01 368-8097

[email protected]

www.stiebel-eltron.hu

Japan

NIHON STIEBEL Co. Ltd.

Kowa Kawasaki Nishiguchi Building 8F

66-2 Horikawa-Cho

Saiwai-Ku | 212-0013 Kawasaki

Tel. 044 540-3200 | Fax 044 540-3210

[email protected]

www.nihonstiebel.co.jp

Netherlands

STIEBEL ELTRON Nederland B.V.

Daviottenweg 36 | 5222 BH ‘s-Hertogenbosch

Tel. 073 623-0000 | Fax 073 623-1141

[email protected]

www.stiebel-eltron.nl

Poland

STIEBEL ELTRON Polska Sp. z O.O.

ul. Działkowa 2 | 02-234 Warszawa

Tel. 022 60920-30 | Fax 022 60920-29

[email protected]

www.stiebel-eltron.pl

Russia

STIEBEL ELTRON LLC RUSSIA

Urzhumskaya street 4,

building 2 | 129343 Moscow

Tel. 0495 7753889 | Fax 0495 7753887

[email protected]

www.stiebel-eltron.ru

Slovakia

TATRAMAT – ohrievače vody s.r.o.

Hlavná 1 | 058 01 Poprad

Tel. 052 7127-125 | Fax 052 7127-148

[email protected]

www.stiebel-eltron.sk

Switzerland

STIEBEL ELTRON AG

Industrie West

Gass 8 | 5242 Lupfig

Tel. 056 4640-500 | Fax 056 4640-501

[email protected]

www.stiebel-eltron.ch

Thailand

STIEBEL ELTRON Asia Ltd.

469 Moo 2 Tambol Klong-Jik

Amphur Bangpa-In | 13160 Ayutthaya

Tel. 035 220088 | Fax 035 221188

[email protected]

www.stiebeleltronasia.com

United Kingdom and Ireland

STIEBEL ELTRON UK Ltd.

Unit 12 Stadium Court

Stadium Road | CH62 3RP Bromborough

Tel. 0151 346-2300 | Fax 0151 334-2913

[email protected]

www.stiebel-eltron.co.uk

United States of America

STIEBEL ELTRON, Inc.

17 West Street | 01088 West Hatfield MA

Tel. 0413 247-3380 | Fax 0413 247-3369

[email protected]

www.stiebel-eltron-usa.com

Subject to errors and technical changes!

Download PDF

Stiebel Eltron SHU 5 SLi comfort SMALL WATER

HEATER User Manual PDF Download