VONROC Reciprocating Saw RS502AC User Manual

1. SAFETY INSTRUCTIONS

Read the enclosed safety warnings, the additional safety warnings and the instructions. Failure to follow the safety warnings and the instructions may result in electric shock, fire and/or serious injury. Save the safety warnings and the instructions for future reference.

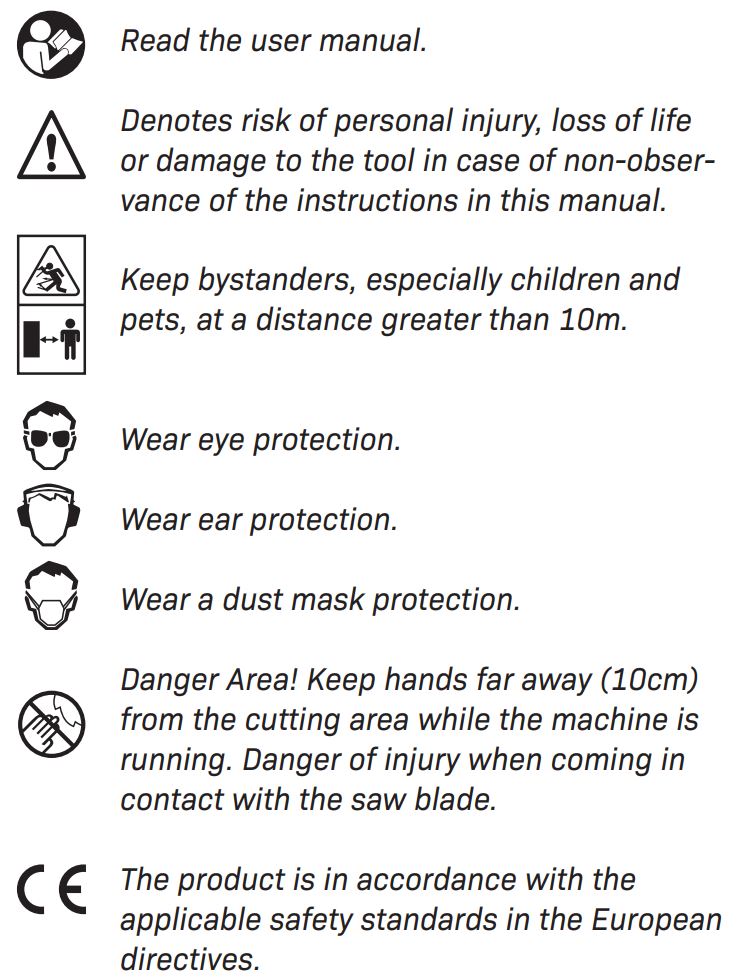

The following symbols are used in the user manual or on the product:

⚠ GENERAL POWER TOOL SAFETY WARNINGS WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference. The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

1) Work area safety a) Keep the work area clean and well lit. Cluttered

or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

b) Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create

sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off position before connecting to power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust related hazards.

h) Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/ or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

h) Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

5) Battery tool use and care

a) Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

b) Use power tools only with specifically designated battery packs. Use of any other battery packs may create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails, screws or other small metal objects that can make a connection from one terminal to another. Shorting the battery terminals together may cause burns or a fire.

d) Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

e) Do not use a battery pack or tool that is damaged or modified. Damaged or modified batteries may exhibit unpredictable behaviour resulting in fire, explosion or risk of injury.

f) Do not expose a battery pack or tool to fire or excessive temperature. Exposure to fire or temperature above 130 °C may cause explosion. NOTE The temperature ,,130 °C” can be replaced by the temperature ,,265 °F”.

g) Follow all charging instructions and do not charge the battery pack or tool outside the temperature range specified in the instructions. Charging improperly or at temperatures outside the specified range may damage the battery and increase the risk of fire.

6) Service

a) Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

b) Never service damaged battery packs. Service of battery packs should only be performed by the manufacturer or authorized service providers.

SAFETY WARNINGS FOR RECIPROCATING SAWS

- Hold power tool by insulated gripping surfaces, when performing an operation where the cut ting accessory may contact hidden wiring. Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

- Keep hands away from the sawing range. Do not reach under the workpiece. Contact with the saw blade can lead to injuries.

- Apply the machine to the workpiece only when switched on. Otherwise there is danger of kickback when the cutting tool jams in the workpiece.

- When sawing, the base plate must always faces against the workpiece. The saw blade can become wedged and lead to loss of control over the machine.

- When the cut is completed, switch off the machine and then pull the saw blade out of the cut only after it has come to a standstill. In this manner you can avoid kickback and can place down the machine securely.

- Use only undamaged saw blades that are in perfect condition. Bent or dull saw blades can break, negatively influence the cut, or lead to kickback.

- Do not brake the saw blade to a stop by applying side pressure after switching off. The saw blade can be damaged, break or cause kickback.

- Clamp material well. Do not support the workpiece with your hand or foot. Do not touch objects or the floor with the the saw running. Danger of kickback.

- Use appropriate detectors to determine if utility lines are hidden in the work area or call the local utility company for assistance. Contact with electric lines can lead to fire and electric shock. Damaging a gas line can lead to explosion. Penetrating a water line causes property damage.

- When working with the machine, always hold it firmly with both hands and provide for a secure stance. The power tool is guided more secure with both hands.

- Secure the workpiece. A workpiece clamped with clamping devices or in a vice is held more secure than by hand.

- Always wait until the machine has come to a complete stop before placing it down. The tool insert can jam and lead to loss of control over the power tool.

2. MACHINE INFORMATION

Intended use

The machine is intended for sawing wood, plastic and metal while keeping the baseplate resting firmly on the workpiece. It is suitable for straight and curved cuts. It is also possible to cut flush to the workpiece surface. A suitable saw blade must always be used.

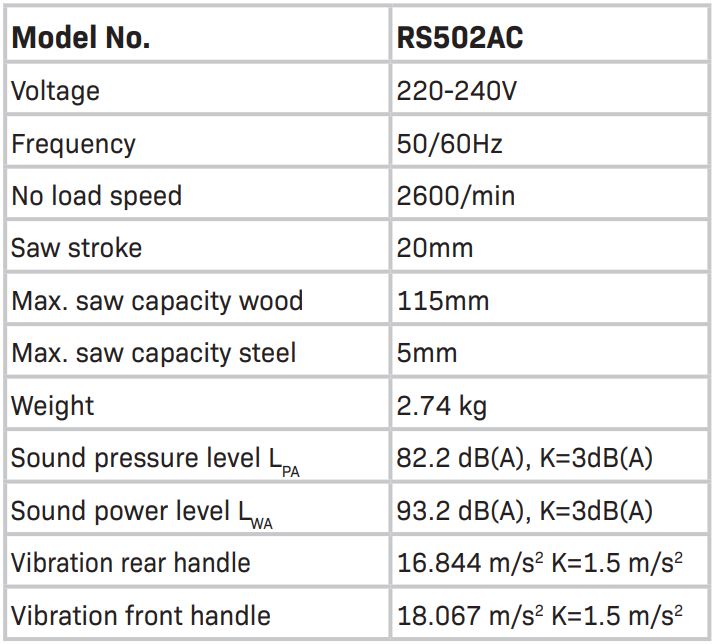

TECHNICAL SPECIFICATIONS

Vibration level

The vibration emission level stated in this instruction manual has been measured in accordance with a standardized test given in EN60745; it may be used to compare one tool with another and as a preliminary assessment of exposure to vibration when using the tool for the applications mentioned.

- Using the tool for different applications, or with different or poorly maintained accessories, may significantly increase the exposure level.

- The times when the tool is switched off or when it is running but not actually doing the job, may significantly reduce the exposure level.

Protect yourself against the effects of vibration by maintaining the tool and its accessories, keeping your hands warm, and organizing your work patterns.

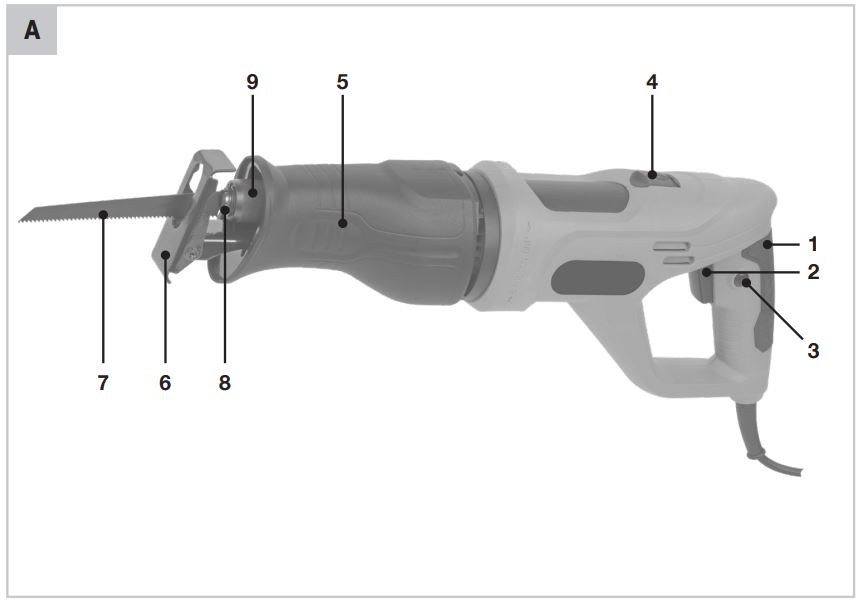

DESCRIPTION The numbers in the text refer to the diagrams on page 2-3.

- Handle

- Lock-on button

- On/Off button

- Handle unlock button

- Auxiliary handle

- Baseplate

- Saw blade

- Chuck

- Clamping lever

- Baseplate bolts

3. ASSEMBLY

⚠ Before carrying out any work on the machine, disconnect the mains plug from the power supply.

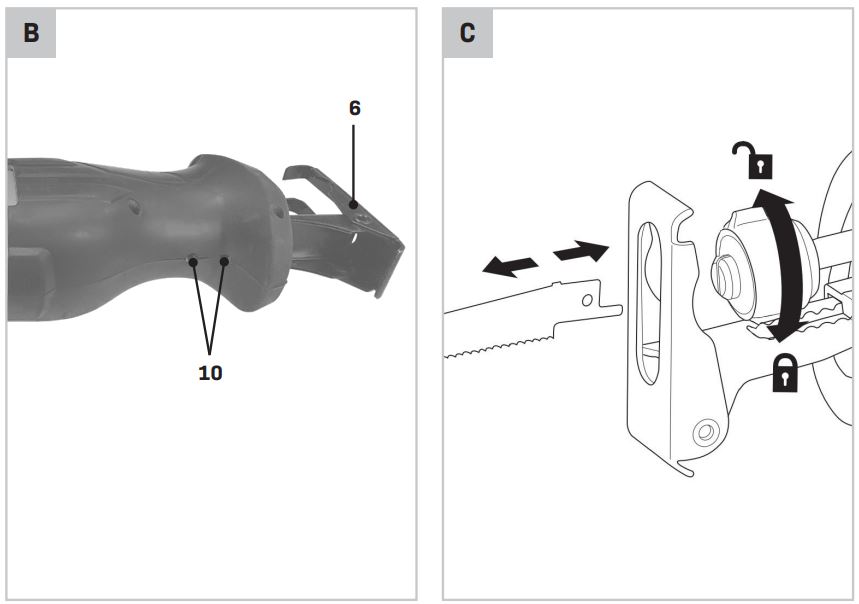

Replacing the saw blade (Fig. A, C)

⚠ When mounting the saw blade, wear protective gloves. Danger of injury when touching the saw blade.

⚠ Only use saw blades that correspond with the characteristic data given in the operating instructions.

Mounting the saw blade

⚠ Make sure the blade holder is free of material debris (such as splinters of wood or metal).

- Turn the clamping lever (9) as far to the left as possible and hold it in this position.

- Insert the saw blade in the chuck (8). Check that the saw blade is securely fixed and that the teeth are pointing downwards.

- Let go of the clamping lever. Check whether the saw blade is locked in place.

Make sure to use the right sawblade for the corresponding material. Included with the machine is a coarse sawblade for wood and a fine sawblade for metal and plastics.

Removing the saw blade

- Turn the clamping lever (9) as far to the left as possible and hold it in this position.

- Remove the saw blade from the chuck (8).

- Let go of the clamping lever.

4. OPERATION

Switching on and off (Fig. A)

- To switch on the machine, press the on/off switch (3).

- To switch the machine to continuous mode, keep the on/off switch (3) pressed and simultaneously press the lock-on button (2).

- To switch off continuous mode, press the on/off switch (3) again.

- To switch off the machine, release the on/off switch (3).

Adjusting the base plate (Fig. B)

Due to its movability, the baseplate (6) angle adapts to the workpiece. Furthermore, the length of the baseplate can be adjusted depending on the required sawing depth.

- Loosen the baseplate bolts (10) using the hex key provided.

- Adjust the baseplate (6).

- Tighten the baseplate bolts (10) using the hex key provided.

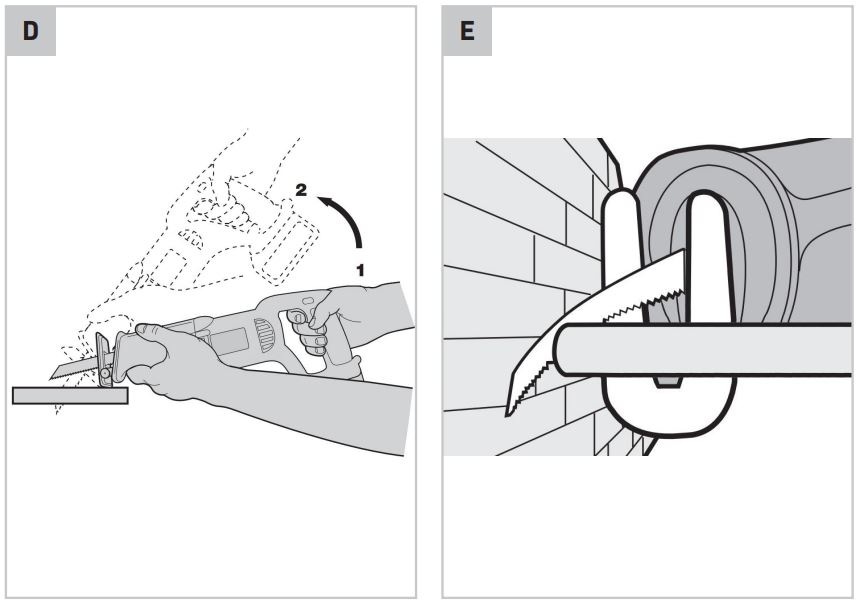

Plunge cutting (Fig. D)

Plunge cutting may only be used on soft materials such as wood, aerated concrete, gypsum plaster boards, etc. However, this requires a certain practise and is only possible with short saw blades.

- Place the saw onto the workpiece and switch it on.

- Ensure that the bottom edge of the footplate rests on the workpiece surface as shown.

- Slowly saw into the workpiece at an angle, moving the saw to a vertical position and continue to saw along the cutting line.

- Switch the saw off and lift off the workpiece when the work is complete.

Flush cutting (Fig. E)

Elastic bi-metal saw blades allow you to saw protruding objects (e,g, water pipes, iron bars, etc,) nearby the wall.

- Apply the saw blade directly to the wall and bend slightly so that the footplate rests against the wall. Pay attention that the saw blade always extends beyond the diameter of the material being worked.

- Switch the machine on and saw off the workpiece keeping constant lateral pressure against the wall.

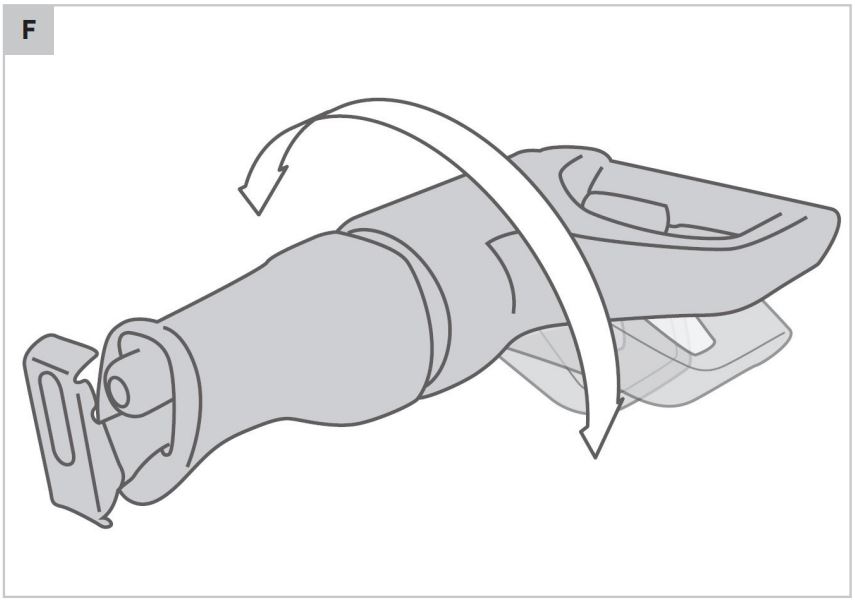

Adjusting the main handle

Before starting operation you can adjust the main handle (1) to the position most comfortable for the task. The handle can be set up in 5 positions within 180° rotation range in long axis of the tool body (90° left or right from the base position).

- Move the handle unlock button (4) back.

- Rotate the main handle around long axis of the tool to desired position (fig. F).

- The main handle automatically locks in desired position.

Optimum use

- Adjust saw blade and stroke rate to suit the material to be processed. For right radius curves it is best to use a narrow saw blade. Apply coolant or lubricant to deal with the fluttering produced along the cut line when sawing metal.

- Check wood, chip boards, building materials etc, for hard materials (nails, screws etc.), before sawing and remove them, if necessary.

- Clamp material well. Do not support the workpiece with hand or foot. Do not touch objects or the floor with the saw running (danger of backlash).

- Put the footplate on the surface of the workpiece, and saw through it with constant contact pressure or feed. If the saw blade seizes switch the machine off immediately. Spread the gap with a suitable tool and pull out the saw blade.

- After finishing work, switch off the machine and only put down after it has come to a complete standstill.

5. MAINTENANCE

⚠ Before cleaning and maintenance, always switch off the machine and remove the battery pack from the machine.

Clean the machine casings regularly with a soft cloth, preferably after each use. Make sure that the ventilation openings are free of dust and dirt. Remove very persistent dirt using a soft cloth moistened with soapsuds. Do not use any solvents such as gasoline, alcohol, ammonia, etc. Chemicals such as these will damage the synthetic components.

ENVIRONMENT

![]() Faulty and/or discarded electrical or electronic apparatus have to be collected at the appropriate recycling locations.

Faulty and/or discarded electrical or electronic apparatus have to be collected at the appropriate recycling locations.

Only for EC countries

Do not dispose of power tools into domestic waste. According to the European Guideline 2012/19/EC for Waste Electrical and Electronic Equipment and its implementation into national right, power tools that are no longer usable must be collected separately and disposed of in an environmentally friendly way.

WARRANTY

VONROC products are developed to the highest quality standards and are guaranteed free of defects in both materials and workmanship for the period lawfully stipulated starting from the date of original purchase. Should the product develop any failure during this period due to defective material and/or workmanship then contact VONROC directly.

The following circumstances are excluded from this guarantee:

- Repairs and or alterations have been made or attempted to the machine by unauthorized service centres;

- Normal wear and tear;

- The tool has been abused, misused or improperly maintained;

- Non-original spare parts have been used.

This constitutes the sole warranty made by company either expressed or implied. There are no other warranties expressed or implied which extend beyond the face hereof, herein, including the implied warranties of merchantability and fitness for a particular purpose. In no event shall VONROC be liable for any incidental or consequential damages.

The dealers remedies shall be limited to repair or replacement of nonconforming units or parts.

The product and the user manual are subject to change. Specifications can be changed without further notice.

![]() DECLARATION OF CONFORMITY RS502AC – RECIPROCATING SAW

DECLARATION OF CONFORMITY RS502AC – RECIPROCATING SAW

We declare under our sole responsibility that this product is in conformity with directive 2011/65/EU of the European parliament and of the council of 8 June on the restriction of the use of certain hazardous substances in electrical and electronic equipment is in conformity and accordance with the following standards and regulations:

2011/65/EU, 2014/30/EU, 2006/42/EC, EN 62841-1, EN 62841-2-11, EN 55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3-3, 2012/19/EU

Zwolle, 01-10-2021

VONROC • Lingenstraat 6 • 8028 PM Zwolle • The Netherlands

©2021 VONROC

WWW.VONROC.COM

2110-11

PDF Download

VONROC Reciprocating Saw RS502AC

User Manual PDF Download